Petrosolutions takes good care of its customers and offers service support for each of our products both during and post warranty period. Our service team offers technical support in cases of product malfunctions, repair, calibration, installation and commissioning. We are WIKA Authorized Calibration & Service Center offering full repair and calibration of the complete product line with factory fresh, new parts. Our Service Center is very skilled and experienced with handling custom assembly packages specific to our customer needs and specifications. If you would like to learn more, do not hesitate to contact us

Petrosolutions is a ISO17025:2017 certified calibration service provider. We Undertake calibration of field Pressure, Temperature, Flow, Level instruments and recalibration of Master calibration Equipment’s. We are WIKA Authorized Calibration & Service Center offering full repair and calibration service.

Our Calibration lab has sophisticated Master testing and Calibration instruments with valid test certificates and traceability which enable us to calibrate almost all range of field instruments.

● Installation Supervision of all types of field instruments in accordance with the approved P&ID.

● Installation Supervision of Pressure transmitters, Pressure gauge’s, Temperature transmitters, temperature elements and level instruments.

● Supervising the cable tray, cable laying and base frame erection in accordance with the approved drawings.

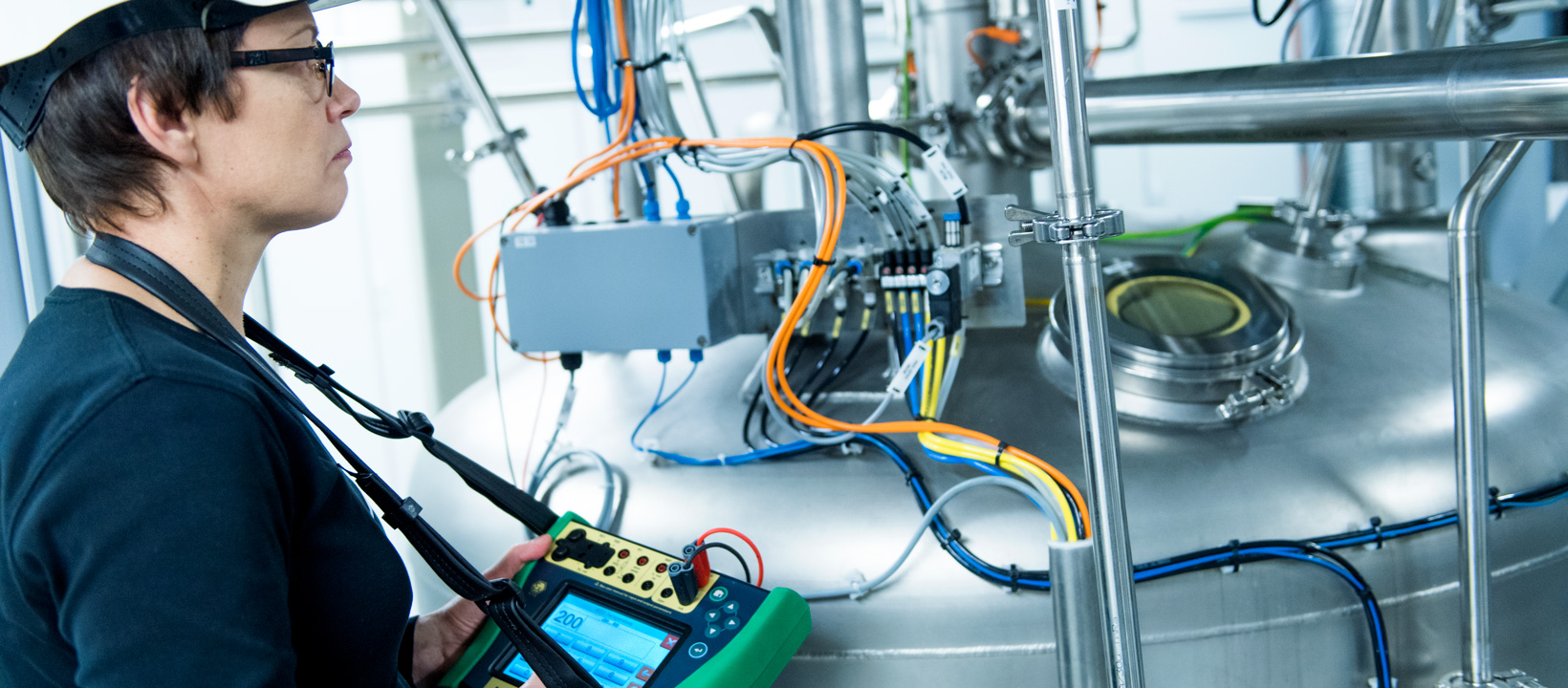

● Connecting the Handheld Programmer and Running communication test.

● Powering up the transmitters until stabilized.

● Zero and Ranging the Transmitters by use of HART/MFM Handheld Communicator as per Data sheet.

●Installation of all type of field instruments as per P&I Drawings.

●Glanding and cable Termination in Instruments, junction Boxes & Marshalling Panels for DCS or PLC system.

●Installation of stanchions/Supports and Canopy for instruments.

●Process loop checking of field Instrument.

●Impulse tubing for instruments as per Hook up Drawings.

●Copper & S.S Tubing for all types of control valves/ON-OFF Valves.

●Laying & clamping of single pair/ Multicore cables.

●Laying of perforated/Ladder type cable tray and fixing the cable tray bends according to the cable route.

●Commissioning, Trouble shooting and calibration of Solenoid valves.

●Commissioning, Trouble shooting and calibration of control valves.

●Commissioning and calibration of pneumatic positioner, I/P Converter, Electro Pneumatic positioner, position feedback transmitters and Smart Positioners.

●Installation, Commissioning and calibration of motorized valves by

●Process loop checking of field Instrument.

●Checking up Cold and Hot Loop checking for the control loops.

●Ensuring Dual Power Supply Change over without affecting the system/Process.

●Checking of Nest Loading as per the I/O allocation for maintaining the redundancy.

●Confirm of all inter-connector cables have been installed in accordance with the reference documents.

●Check of all I/O cabling to field devices and the field devices are installed and comply with the reference documents.

●Uploading and Downloading the program, Logic design, nest loading and I/O assignment, graphic design and implementation for SIEMENS S7300 & 400and its WinCC, ABB 800XA, AC 900F, Yokogawa Cs3000 & Centum VP, Annunciator and SOE.

●Checking System Architecture according to the approved drawings.